Products&Technology

Al-plastic film

Summary:As a packaging material for flexible packaging lithium battery cells, Andeli's A series aluminum-plastic soft packaging composite film has excellent barrier performance, deep forming performance, electrolyte stability and electrical insulation performance.

Keyword:PEVA packaging film, PE protective film

Category:

Product description

As the packaging material for flexible packaging lithium battery cells, Andre's A-series aluminum-plastic soft packaging composite film has excellent barrier performance, deep drawing performance, electrolyte resistance stability and electrical insulation performance. The product has good compatibility with various ear products on the market, and is widely used in small electronic consumer products such as smart phones, notebook computers, and tablet computers; power battery products such as power tools, electric motorcycles, and new energy vehicles.

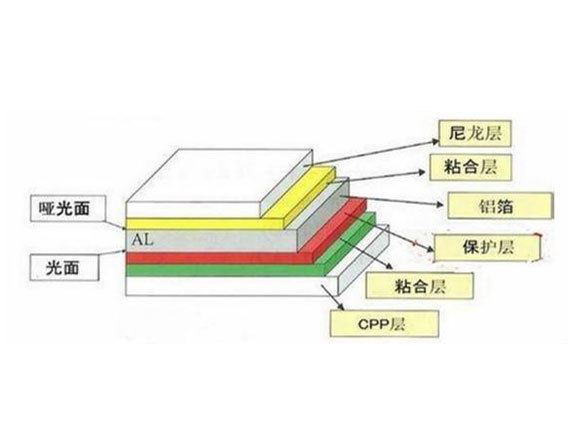

product structure

Product model and specification

|

Model |

Thickness |

width |

Length |

|

A112 |

112 |

400mm |

250m |

|

A152 |

152 |

400mm |

250m |

Remarks: Length specification and width specification can be negotiated by both parties

Performance Indicators

Type A112

|

Project |

Standard |

Methods and Conditions |

Test value |

|

|

Appearance |

Pinhole |

No pinholes |

Light box detection |

Meet the requirements |

|

Scratches |

Ony layer scratches≤10mm |

Visual inspection |

Meet the requirements |

|

|

Stain |

No stain |

Visual inspection |

Meet the requirements |

|

|

Physical properties |

ONy/AL Peel Strength |

≥4.0N/15mm |

GB/T18008: Stripping angle 180° |

≥4.0N/15mm |

|

CPP/AL Peel Strength |

≥8.0N/15mm |

GB/T18008: Stripping angle 180° |

≥10N/15mm |

|

|

Heat sealing performance |

≥45N/15mm |

QB/T2358: |

≥60N/15mm |

|

|

Formability |

≥5.0mm |

Q/SADL 2: |

≥6.5mm |

|

|

Friction Coefficient |

<0.5 |

GB/T10006 |

<0.35 |

|

|

Electrolyte resistance |

CPP/AL adhesion |

CPP/AL is not stratified |

Q/SADL 2: |

Meet the requirements |

|

CPP/AL Peel Strength |

≥5.0N/15mm |

Q/SADL 2: |

≥8.0N/15mm |

|

|

Electrical insulation performance |

≥20MΩ |

Multimeter |

Meet the requirements |

|

|

Halogen detection |

SGS |

SGS |

Meet the requirements |

|

|

ROHS testing |

SGS |

SGS |

Meet the requirements |

|

Type A152

|

Project |

Standard |

Methods and Conditions |

Test value |

|

|

Appearance |

Pinhole |

No pinholes |

Light box detection |

Meet the requirements |

|

Scratches |

Ony layer scratches≤10mm |

Visual inspection |

Meet the requirements |

|

|

Stain |

No stain |

Visual inspection |

Meet the requirements |

|

|

Physical properties |

ONy/AL Peel Strength |

≥4.0N/15mm |

GB/T18008: Stripping angle 180° |

≥4.0N/15mm |

|

CPP/AL Peel Strength |

≥8.0N/15mm |

GB/T18008: Stripping angle 180° |

≥12N/15mm |

|

|

Heat sealing performance |

≥60N/15mm |

QB/T2358: |

≥80N/15mm |

|

|

Formability |

≥5.0mm |

Q/SADL 2: |

≥6.5mm |

|

|

Friction Coefficient |

<0.5 |

GB/T10006 |

<0.35 |

|

|

Electrolyte resistance |

CPP/AL adhesion |

CPP/AL is not stratified |

Q/SADL 2: |

Meet the requirements |

|

CPP/AL Peel Strength |

≥5.0N/15mm |

Q/SADL 2: |

≥8.0N/15mm |

|

|

Electrical insulation performance |

≥20MΩ |

Multimeter |

Meet the requirements |

|

|

Halogen detection |

SGS |

SGS |

Meet the requirements |

|

|

ROHS testing |

SGS |

SGS |

Meet the requirements |

|

Complete categories and cost-effective

With professional technology, we are committed to product research and development, create cost-effective products, and meet the needs of customers.

Good quality is trustworthy

Quality management is embedded in every production process during the production process. From raw material selection to product production

Manufacturing, packaging, shipment, etc. are inspected and supervised layer by layer, and strive to create excellent quality.

Worry-free after-sales service

Meticulous service details highlight service quality!

Related products

Get a free product quote

We are an emerging sunrise enterprise with a strong brand awareness and a high level of innovation spirit that grows in sync with the new century and new concepts.

service@gdandeli.com

service@gdandeli.com

86-754-85709138

86-754-85709138

http://www.gdandeli.com

http://www.gdandeli.com

Andeli Industrial Park, Xiadao Road, Chenghai District, Shantou City, Guangdong Province

Andeli Industrial Park, Xiadao Road, Chenghai District, Shantou City, Guangdong Province

Contact Information

Official account

Website

Copyright @ Guangdong ANDELI New Materials Co., Ltd Power by:www.300.cn SEO License